The services that Mavida Projects provide have been simplified by breaking them down into six categories. Many of the categories are inter-dependent, but make up the skill sets required to take a project from early concept through to prototype manufacture & testing.

- Project Management

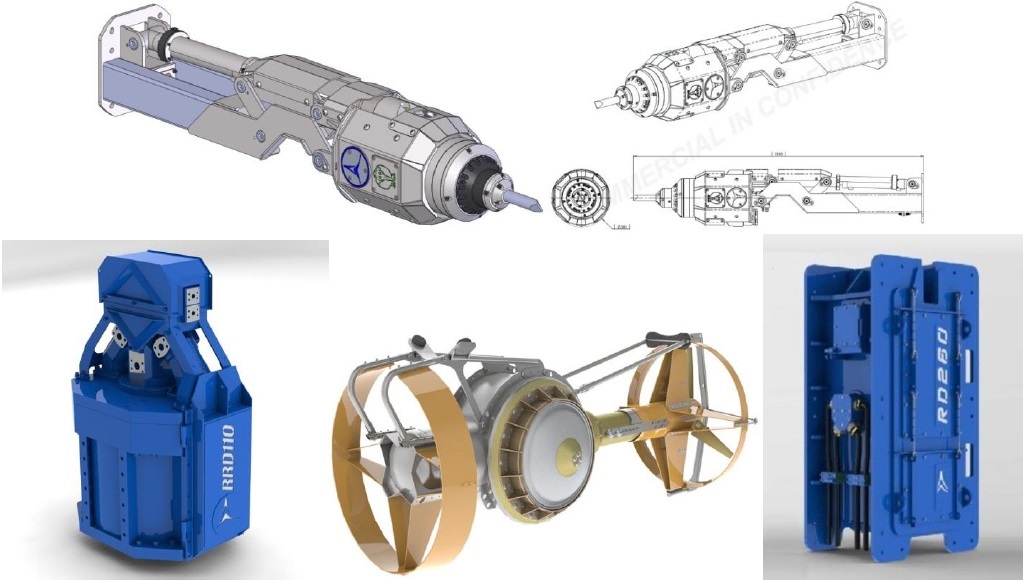

- 3D Mechanical Design, Technical Detailing, Rendering & Animation

- Engineering Analysis

- Prototype Manufacture & Assembly

- Research & Development

- Technical Support

Depending on your project requirements, we can customise the service we provide. You may just need 3D Mechanical Design & Technical Detailing. The design may need some Engineering Analysis to justify critical areas. We will be guided by you, but we will keep you informed about what the project may need.

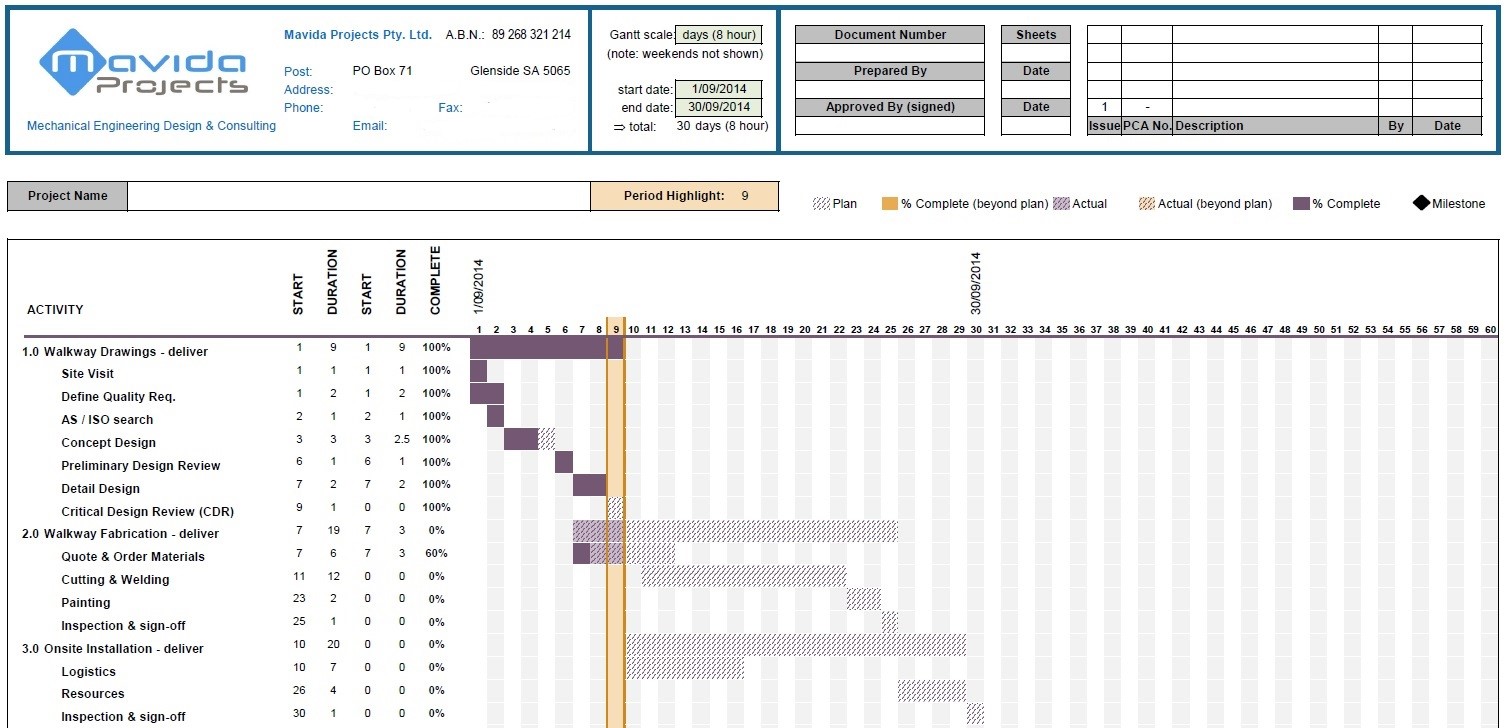

Project Management

This is the most comprehensive service, taking your initial concept through to the assembly & testing of the prototype (refer ‘Methodology’). We will guide you through the initiation, planning, execution & closure phases of the project. This service can encompass all the other services that Mavida Projects provides and includes:

- Coordination of all suppliers and other stakeholders to maintain delivery schedule.

- Work with the client to develop & manage the project scope

- Establish & control the project budget

- Maintain quality (AS/ISO, internal & client expectations)

- Keep stakeholders informed with relevant the status of the project.

3D Mechanical Design, Technical Detailing, Rendering & Animation

We use SolidWorks to generate parametric 3D CAD models which can then be readily translated into technical drawings and parts lists. The 3D modelling environment allows the designer & client to easily visualise complex geometries during design. We can also generate exploded views of the assemblies, ideal for physical assembly instructions and maintenance manuals.

The 3D CAD parts & assemblies can be readily manipulated to produce life-like images. Using Photoworks (a SolidWorks add-in program), we can add lighting, textures and backgrounds to generate high quality still renderings or animations. These can be perfect for visualisation and promotional material.

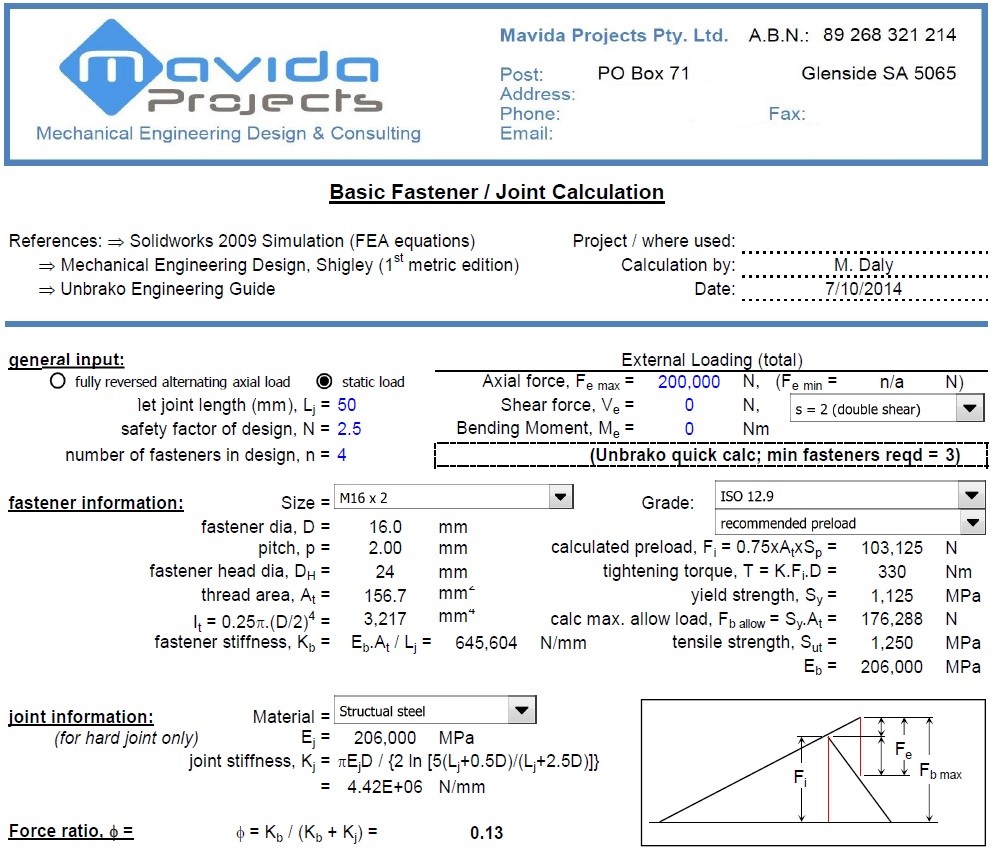

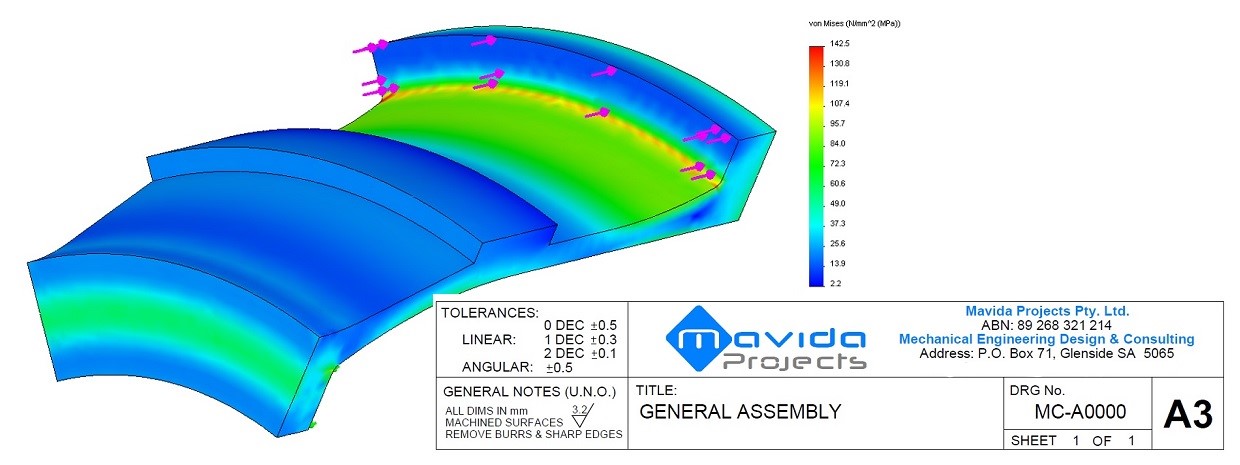

Engineering Analysis

There are a number of ways we can justify the integrity of a new design before committing to costly manufacture. Engineering analysis can include Excel based calculations and/or full Finite Element Analysis (FEA).

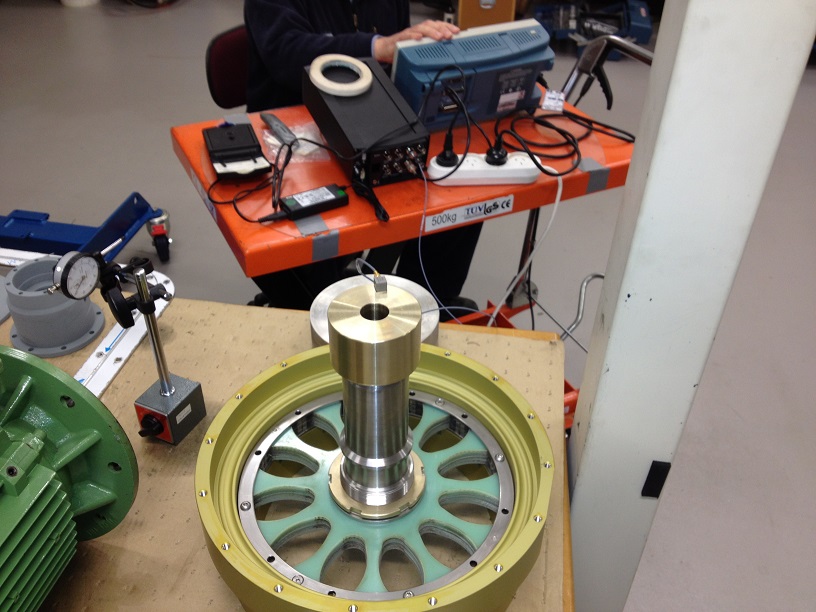

Prototype Manufacture & Assembly

Detail drawings, generated from the 3D CAD models, are sent out to our network of quality suppliers for quotes. The CAD model is available for CNC programming, 2D profiles can also be generated for profile cutting.

Research & Development

This can occur during a project to verify design, or as a continuous improvement mechanism to support existing products. The R&D can include (but not limited to):

- Lab testing – where required, modules are built & fully tested to ensure they fulfil requirements.

- Field testing – after the prototype has been built, the complete machine is tested

- Continuous improvement – looking into ways to improve reliability, reduce costs and improve manufacturability.

Technical Support

There are many additional services we can provide

- Technical Report compilation. These can be generated throughout the project and may include the Preliminary Design Review (PDR), Critical Design Review (CDR), R&D and results from trials, background research etc.

- Maintenance & Operator Manuals. A comprehensive set of instruction manuals, including 3D CAD exploded and section views.

- Training course. We use the maintenance & operator manuals as the basis of our training course. Training teaches the end users/maintainers how to use & maintain the equipment.

- Phone/email support